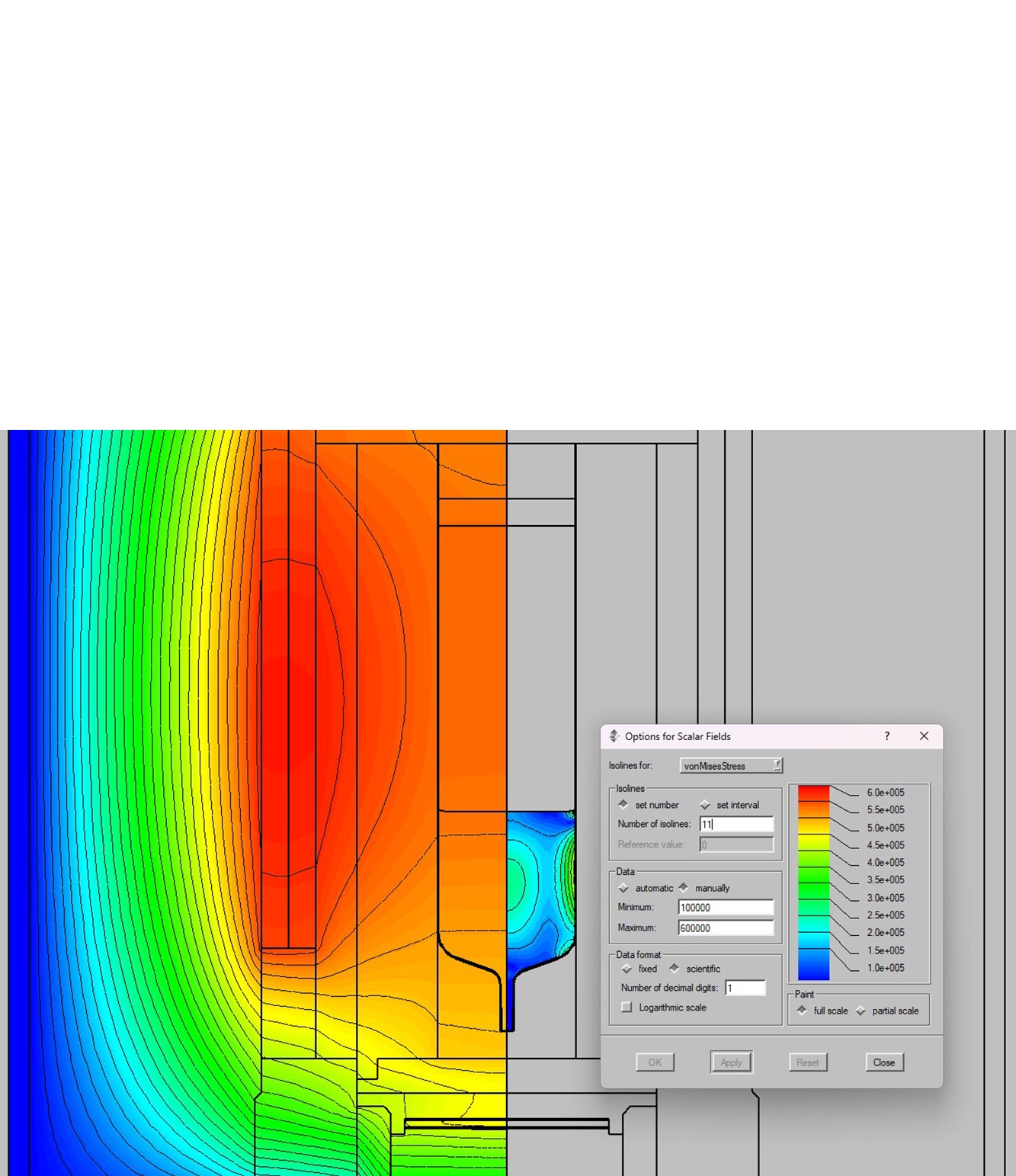

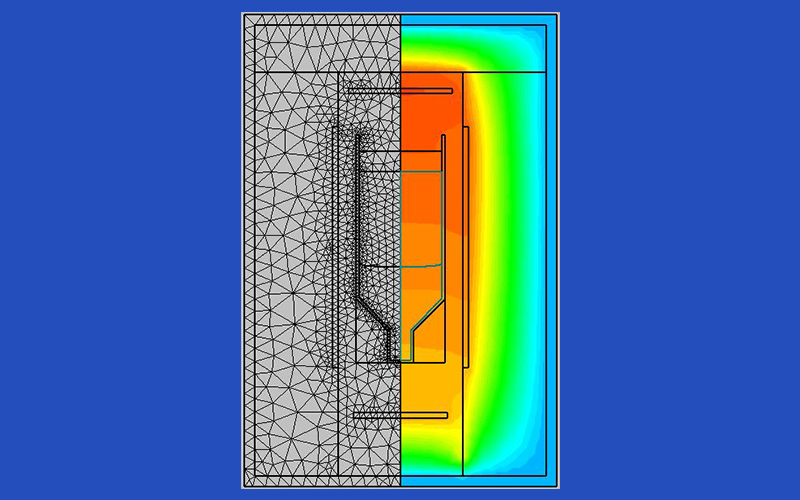

Improving crystal growth requires a deep understanding of thermal dynamics. Our thermal simulation services for VGF (Vertical Gradient Freeze) furnace design and the crystal growth process allow you to optimize the entire procedure without expensive, time-consuming physical prototypes.

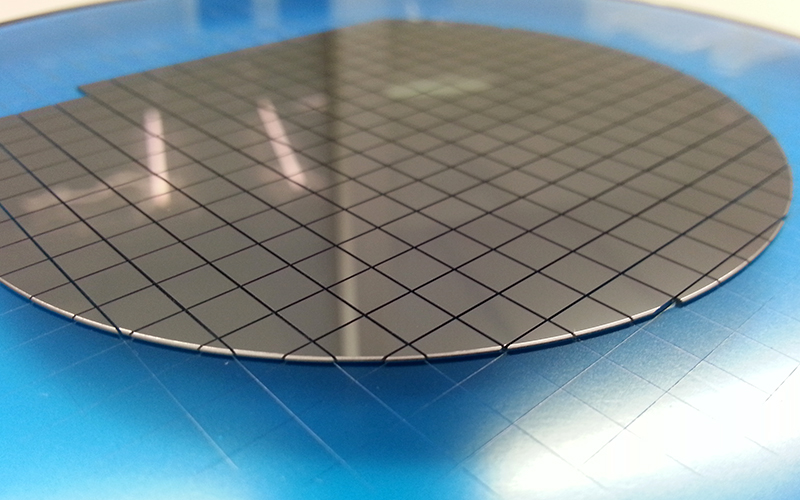

By precisely modeling heat transfer, temperature gradients, and the resulting stress levels throughout the entire growth run, we help you achieve a controlled and optimized temperature field. This is a critical factor for producing high-quality, low-defect crystals. From fine-tuning heater configurations to improving insulation and material choices, our simulations provide the insights needed to accelerate your R&D, reduce material waste, and increase the yield of flawless crystals for your most demanding applications.

CORE PRODUCTS, SERVICES AND APPLICATIONS

Our SOLUTIONS